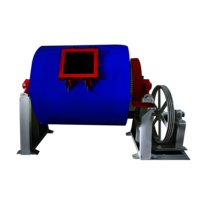

Ball Mill

Delivery Time : 7 Days

Call us now

08045812069

Delivery Time : 7 Days

Supply Ability 1 Per Week

Delivery Time 7 Days

SPECIFICATION

| Brand | Chem Maco |

| Material | Stainless Steel & Mild Steel |

| Capacity | 200L,300L,600L,1400L,2000L,3000L |

| Type | Batch Type |

| Phase | 3 Phase |

| Automation Grade | Semi-Automatic |

| Use | For dry and wet grinding and mixing |