Call us now

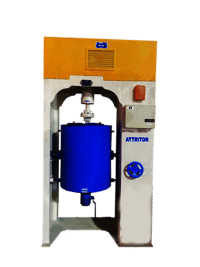

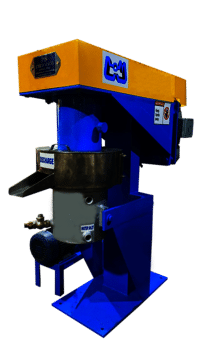

08045812069Attritor Mill

Minimum Order Quantity : 100 Pieces

Delivery Time : 7 Days

Supply Ability 1 Per Week

About this product

SPECIFICATION

| Material | Stainless Steel & Mild Steel |

| Brand | Chem Maco |

| Vessel capacity | 5L, 25L, 50L, 100L, 200L, 300L, 550L |

| Frequency | 50 Hz |

| Driven Type | Electric |

| Voltage | 440 Volts & 220 Volts |

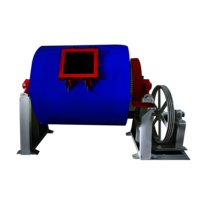

Ball Mill

Delivery Time : 7 Days

Supply Ability 1 Per Week

About this product

SPECIFICATION

| Brand | Chem Maco |

| Material | Stainless Steel & Mild Steel |

| Capacity | 200L,300L,600L,1400L,2000L,3000L |

| Type | Batch Type |

| Phase | 3 Phase |

| Automation Grade | Semi-Automatic |

| Use | For dry and wet grinding and mixing |

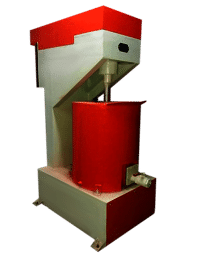

Shroud Ball Mill

Delivery Time : 7 Days

Supply Ability 1 Per Week

About this product

SPECIFICATION

| Brand | Chem Maco |

| Material | Stainless Steel & Mild Steel |

| Power Source | Electric |

| Size | 200 Kgs - 4000 Kgs. |

| Phase | 3 Phase |

| Type | Batch Type |

| Usage/Application | Dry Cement Paint, Cement Base Wall Putty and Other Allied Items etc |

| Capacity | 1 to 4000L |

Water Cooling Ball Mill

About this product

SPECIFICATION

| Brand | Chem Maco |

| Material | Stainless Steel & Mild Steel |

| Power Source | Electric |

| Phase | Three |

| Type | Batch Type |

| Usage/Application | Paints,Primers,Bituminous Paints and other related items. |

| Capacity | 100 to 4000L |

Floor Oxide Paint Manufacturing Machine

About this product

SPECIFICATION

| Power Source | Electric |

| Size | 100 Kgs. - 4000 Kgs. |

| Type | Batch Type |

| Usage/Application | Paints,Primer,Floor Oxide,Dry Cement Paint,Cement Base Wall Putty,Tile Fixing Compound,Constr |

| Capacity | 100 Kgs. - 4000 Kgs. |

| Phase | Three Phase |

| Frequency | 50 Hz |

| Voltage | 440 Volts & 220 volts |

| Material | Stainless Steel & Mild Steel |

| Brand | Chem Maco |

Cement Paint Manufacturing Machine

About this product

SPECIFICATION

| Phase | Three |

| Type | Batch Type |

| Capacity | 200 Ltrs - 4000 Ltrs |

| Volume | 200 Ltrs - 4000 Ltrs |

| Power Source | Electric |

| Frequency | 50 Hz |

| Voltage | 440 Volts & 220 Volts |

| Material | Stainless Steel & Mild Steel |

| Brand | Chem Maco |

Paint Processing Machine

About this product

SPECIFICATION

| Color | As per requirement. |

| Frequency | 50 Hz |

| Voltage | 440 Volts & 220 Volts |

| Power Source | Electric |

| Material | Stainless Steel & Mild Steel |

| Brand | Chem Maco |

Industrial Ball Mill

About this product

SPECIFICATION

| Brand | Chem Maco |

| Material | Stainless Steel & Mild Steel |

| Voltage | 380V |

| Power Source | electric |

| Phase | three |

| Type | batch type |

| Automation Grade | Automatic |

| Used In | Cement and Paint Industry |

| Frequency | 50 Hz |

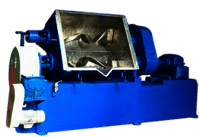

Batch Type Bead Mill

Minimum Order Quantity : 100 Pieces

Delivery Time : 7 Days

Supply Ability 1 Per Week

About this product

SPECIFICATION

| Brand | Chem Maco |

| Frequency | 50 Hz |

| Phase | three |

| Capacity | 200L, 300L, 600L, 1400L, 2000L, 3000L |

| Use | For dry and wet grinding and mixing |

| Material | Stainless Steel & Mild Steel |

Colour Mixing Machine

About this product

SPECIFICATION

| Usage/Application | Industrial |

| Material | Mild Steel |

| Brand | Chem Maco |

| Design Type | Customized |

| Country of Origin | Made in India |

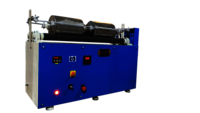

Jar Mill

Minimum Order Quantity : 100 Pieces

Delivery Time : 7 Days

Supply Ability 1 Per Week

About this product

Product Details:

| Material | Stainless Steel |

| Ring Diameter | 'As per Requirement |

| Capacity | 'As per Requirement |

| Power | 'As per Requirement |

We offer our clients with supreme quality of Pot Mills which suitable for Grinding, Crushing, and mixing of small batches of materials in jar/pot. Capacity available single rack or double rack with the jar/pot

• Capacity Available: 1 To 10 Ltrs.

• Advantages:

» Easy cleaning/handling.

» Safe and easy performance.

» Low maintenance cost.

• Applications: For grinding, milling & mixing in laboratory scale.

Technical Details

Sand Mill

Minimum Order Quantity : 100 Pieces

Delivery Time : 7 Days

Supply Ability 1 Per Week

About this product

SPECIFICATION

| Power | 5HP to 25HP |

| Capacity | 5 Liters to 30 Liters |

| Material | Stainless Steel |

| Flame Proof Version | Available |

| Mill Chamber Volume | 5 Liters to 30 Liters |

| Milling Media Type | Zirconium Grinding Beads or Glass Beads |

| Country of Origin | Made in India |

Explore Additional Categories

Contact Us

Our Products

Our Products